Injection molder realizes 400% increase in productivity deploying versatile cobots

In Short

Stacking trays, picking parts off conveyors, and tending machines are just some of the many tedious tasks AIM Processing now has the collaborative robots from Universal Robots (UR) handling. Facing labor shortages, the Colorado injection molder wanted a versatile automation solution that could quickly be moved between work stations to address a multitude of tasks in a high mix/low volume setting. The answer was a mobile platform with a UR5e cobot equipped with Flexx Reference, a feature that enables the cobot to be repurposed in a matter of minutes, delivering a fourfold increase in productivity with a payback of less than 15 weeks.

The business transformation

AIM Processing produces over 1300 different parts for more than 100 different customers in a variety of industries. “Every day is new here with very few production runs set up for a long time,” says owner Jon Gelston, who also faced an extremely scarce labor market. “That really sparked us to look into automation, to find ways to increase our output and control our costs,” says Gelston, who started searching for a versatile and modular automation solution. His team had come across Universal Robots at a tradeshow a few years earlier. “It struck us as something that had potential to work in our environment,” says the AIM Processing owner, who went ahead and purchased a UR5e cobot.

AIM Processing

Jon Gelston, Owner, AIM ProcessingFrom our very first application, the cobot far surpassed our expectations in terms of productivity increase.

Challenge moving cobot between applications

“Once we got it up and running, it was a beautiful thing and we wanted to move the robot around between applications,” says Gelston. “The challenge, however, was next time we would go set it up and all the time we would need to spend to reteach the waypoints the robot moves through in free space,” he explains, emphasizing how accuracy to 0.5mm was necessary at some points. “It is one thing to get something working once, but without a dedicated production line and the UR5e locked into an exact position, how would we set this up again?”

Applications

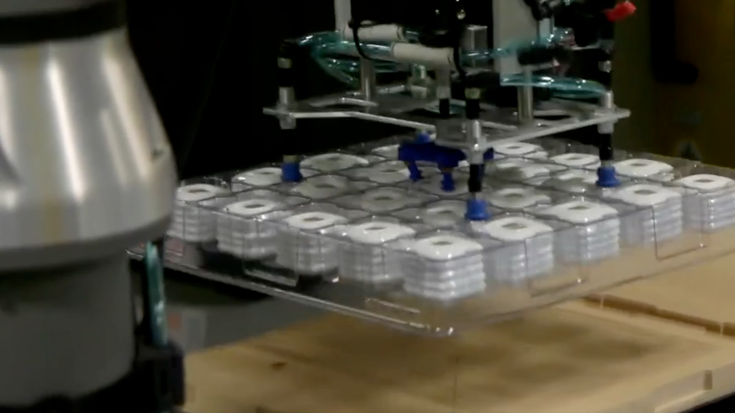

One of the applications, for example, has the UR5e picking and placing trays in front of a cartesian robot that palletizes small parts into compartments on the tray. The company couldn’t simply launch a stored program used previously for the same application, since the position of the robot could still be slightly off - causing the whole application to be out of sync.

What the walkthrough revealed

The company called up Seth Leinbach, sales engineer with local UR cobot distributor, In-Position Technologies, who did a factory walk-through with Gelston. “We looked at several applications and none were high enough volume to justify a dedicated robot cell,” says Leinbach. “Jon also had plenty of questions on how to repurpose a robot and how to match coordinate systems of the UR to the injection molding machine, and right away I thought it was a perfect fit for a UR+ solution by Flexxbotics called the Flexx Reference.”

Flexx Reference solution

To make sure the cobot is positioned exactly the same every time it returns to an application, AIM Processing is using the Flexx Reference solution from Flexxbotics. When placing the cobot in Flexx Reference’s Lockout Assembly, a 6-degree mechanical mating system, the system captures the cobot’s coordinates with the click of a button in the Flexx Reference software on the cobot’s teach pendant. All the cobot’s programmed waypoints and moves in space are then updated relative to the captured position in the Lockout Assembly. The user can now unlock the cobot and start the program without having to reteach any positions.

Fourfold productivity increase

Since the company’s first cobot deployment, AIM Processing has launched more than a dozen specific applications, having the UR5e tend injection molding machines, stack trays, and pick parts off conveyors. The first goal was to automate the picking and placing of trays for the palletizing cartesian robot. Previously, this was an activity that occurred every 90 seconds with a person sitting and waiting to move the trays for a couple of seconds.

“The benefit of automating this task was not just the obvious labor avoidance. We can now run the machine with a much higher capacity and throughput in a 24/7 operation as opposed to just 40 hours a week. That basically gave us a fourfold increase in our output productivity,” says Gelston, adding that another benefit is consistency: “In terms of our part output, the cycle times are exactly the same, to the second, which leads to a consistent product.”

ROI within 15 weeks

Jon Gelston is often asked how much he paid for the UR5e cobot – and more importantly, how quickly it will pay itself back. “My response is always that it’s not going to pay itself back if you don’t use it,” he says, stressing how the modular deployment really helped drive home the ROI:

“Part of the uncertainty with running a variety of different parts for varying durations makes it difficult in terms of trying to calculate payback; but what I can tell you is that on our very first application, we found that after we ran it the fifth time, we had paid for the robot itself, which meant a ROI inside of 15 weeks,” says the AIM Processing owner who just deployed a second UR5e to roam the factory floor wherever automation is needed.

Training & UR Academy

The AIM Processing team had basic understanding of logic flow and programming prior to working with Universal Robots, “but very little direct experience with robot programming” as owner Jon Gelston puts it, emphasizing the resources he found through the free online portion of the UR Academy. “There were self-training modules in both video and read-along formats that were very helpful for us to find and learn from in terms of applications and improvements in procedures that would benefit a variety of our applications,” he says admitting that; “Our first application was probably, by our standards now, not terribly complicated; but at the time, it did feel like it was. “By utilizing the resources that we found in the UR training database and support site, as well as the Universal Robots’ community of value-added resellers and add-on components, it really enabled that project to come to a great success,” says Gelston.

UR+ products used

Automation challenges solved:

Ability to easily move the cobots between applications Ability to easily interface with peripherals such as grippers and vision cameras Ability to automate high mix/low volume production

Key value drivers:

400% productivity increase Roi in 15 weeks Product quality improved

Tasks solved by collaborative robots

Interfacing with cartesian robot to pick and place trays with finished products. Vision-guided picking of parts off conveyors.

Get in touch with Universal Robots

Thousands of businesses rely on Collaborative Robots to...

- Increase productivity

- Adapt to changing product demand

- Improve employee well-being and retention

- Staff through labor shortages

- Universal Robots USA, Inc

- 27175 Haggerty Road, Suite 160

- 48377 Novi, MI